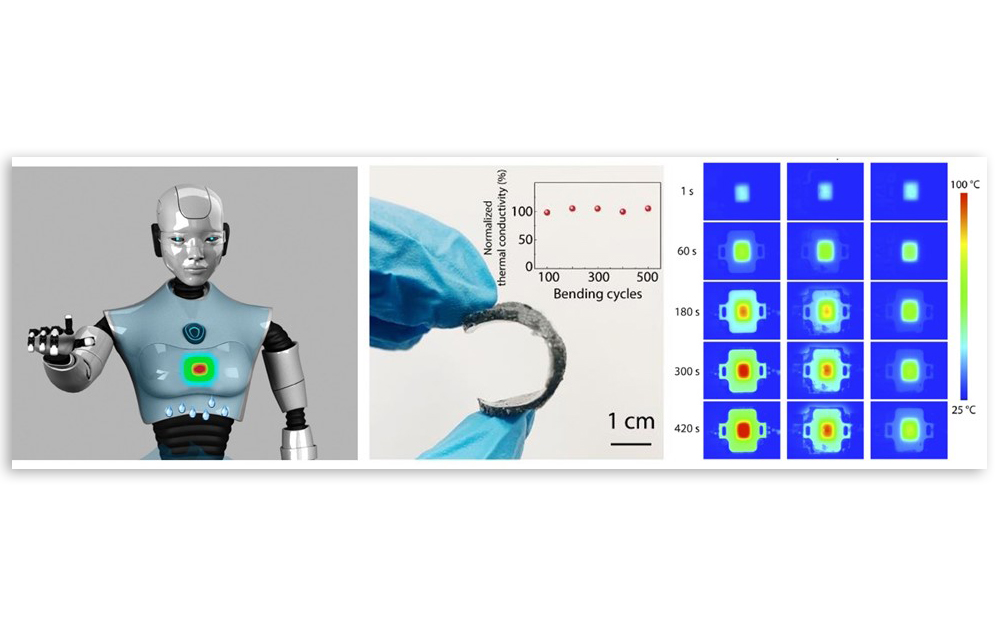

As an emerging field, thermal management for wearable electronics and robots requires advanced building blocks to provide not only efficient heat dissipation but also high softness and flexibility. Using new materials, modeling design, and self-assembled manufacturing, Professor Yongjie Hu’s group report high performance thermal management with excellent elastic compliance similar to that of soft biological tissues down to 100 kPa, high flexibility, and preserves over at least 500 bending cycles a high thermal conductivity over about 100 times improvement of a typical polymer. The superior cooling performance has been verified by device integration with power LEDs to show a 45 °C reduction in the hot spot temperature. Together, this study demonstrates scalable manufacturing of a new generation of energy-efficient and flexible thermal materials that holds great promise for advanced thermal energy technologies.

“We are very excited to tackle the most frontier technology issues,” said Ms. Ying Cui, a mechanical engineering graduate student, “This is another good example that exciting innovations can be demonstrated using the interdisciplinary approaches in our lab. It leads to new research opportunities across boundaries and through the collaborations, e.g. between thermal and robotics engineers”. Other authors of this work include Zihao Qin, Huan Wu, and Man Li and they are all PhD students from Prof. Hu’s research group.

The authors reported their results in the journal Nature Communications. Part of this work is supported by the National Science Foundation and Alfred P. Sloan Foundation.