UCLA mechanical engineers have developed a face mask prototype that uses heat to destroy viruses and other microscopic pathogens.

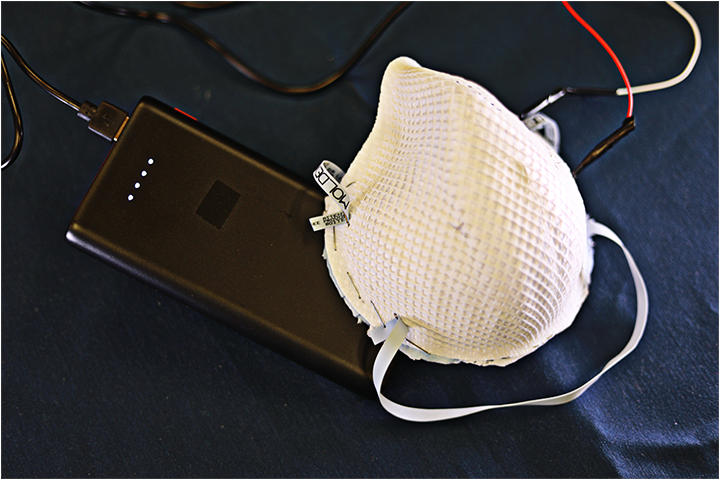

Disposable masks have been used to provide a physical barrier that offers protection for people who may be exposed to airborne viruses and bacteria. The UCLA design is modeled on N95 and KN95 face masks and features metal wires that can be heated in between a mask’s outer and inner layers. The wires, which do not touch the face, are heated to temperatures around 40 degrees Celsius (about 104 degrees Fahrenheit) — sufficient to kill off remaining viruses that get through the outer filter layer.

“Since the onset of the pandemic, face masks have become a standard first line of defense to prevent infection,” said Vijay Dhir, a distinguished professor of mechanical and aerospace engineering at the UCLA Samueli School of Engineering and the lead investigator on the mask’s development. “Our goal here was to make a mask that’s comfortable to wear, with heat as an additional level of protection over the physical barrier. This simultaneously offers improved protection for the wearer, while also preventing their own potential spread of an infection. This could be especially desirable for front-line medical workers or anyone who works in crowded spaces and wants an added level of protection.”

N95 and KN95 masks use physical filters to prevent up to 95% of airborne particles, including viruses, from passing through the masks. In tests, the researchers say their heat-enhanced masks stopped more than 99% of airborne viruses.

“Wearing masks to prevent infections is a habit that will likely stick around in the years to come, even when the COVID-19 pandemic eventually wanes,” Dhir added. “This type of mask could be another option.”

The prototype uses a KN95 material on the outer layer with metal wiring embedded underneath it. The wiring is connected to a small, rechargeable lithium battery pack used to heat up the mask and can be turned on and off by the user. A medical-grade inner layer that touches the face completes the mask. The heating element part of the mask is reusable, while the inner and outer layers can be replaced after each use. The mask is warm to the touch but comfortable to wear over long periods.

To test the heating element in the mask assembly, the team collaborated with Dr. Vaithilingaraja Arumugaswami, a virologist and an associate professor of the Department of Molecular and Medical Pharmacology at the UCLA David Geffen School of Medicine. Virological assays were done at a high containment facility on campus to evaluate the SARS-CoV-2 virus inactivation by the heating component of the mask. SARS-CoV-2 viral solution was placed under the heating element on a petri dish. After one hour of heat treatment, more than 99% of the live infectious virus was inactivated.

The research team has filed for a provisional U.S. patent on the mask design through the UCLA Technology Development Group and plans to submit its findings for peer review. Xiaochun Li, UCLA’s Raytheon Endowed Professor of Manufacturing Engineering is also part of the team that developed the concept.