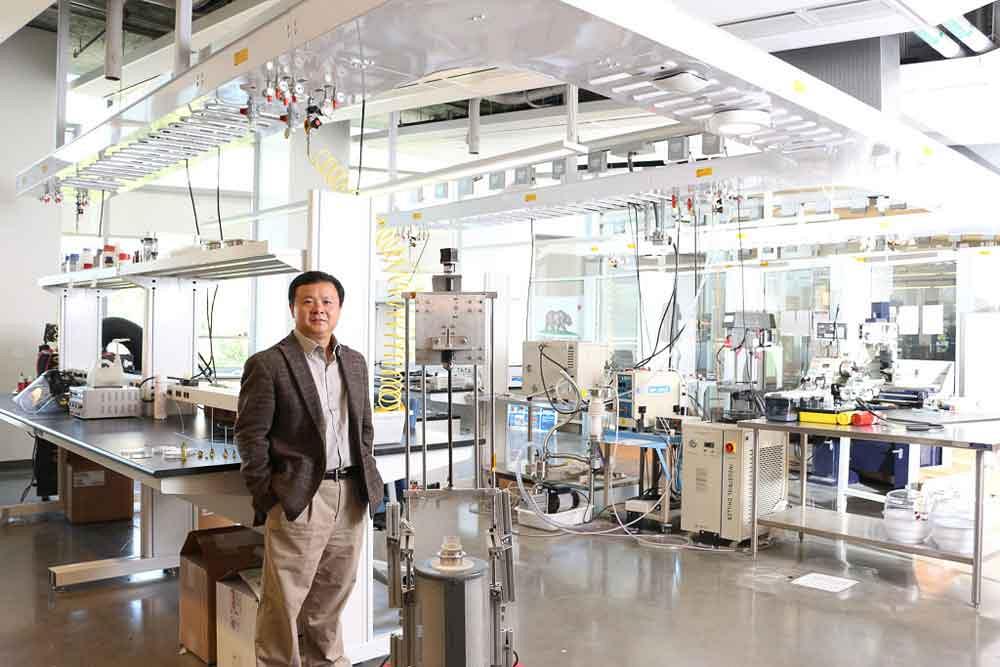

The Fabricator has published a feature article on MAE Prof. Xiaochun Li’s lab technology, “Nanotechnology meets metal fabrication“.

Excerpt:

In late 2018 Travis Widick finished welding a prototype bike frame that looked like any other bike frame, only it wasn’t. The tubular components were aluminum, but not just any grade. They were aluminum 7075.

The aluminum 7075 alloy, widely used in the aerospace industry, is about twice as strong as its widely used cousin, aluminum 6061, but it’s nearly impossible to weld by conventional means without cracking. Until now, that is. Widick used conventional gas metal arc welding with no special shielding gas, welding gun, or power source. In fact, he welded the material slowly, actually intending to increase thermal stress and shrinkage.

Why? He was testing a unique welding wire. Widick works at the UCLA Samueli School of Engineering with professor Xiaochun Li, who in 2016 launched a company called MetaLi to manufacture and market nanoparticle-infused materials. The bike frame base material Widick welded was conventional 7075, but his 7075 welding wire was anything but. It was infused with titanium-based ceramic nanoparticles, dispersed in just the right way so that they became, as Li described them, “the ultimate peacemakers.” Those nano-sized peacemakers made the unweldable weldable.

Please click here to read the full article.