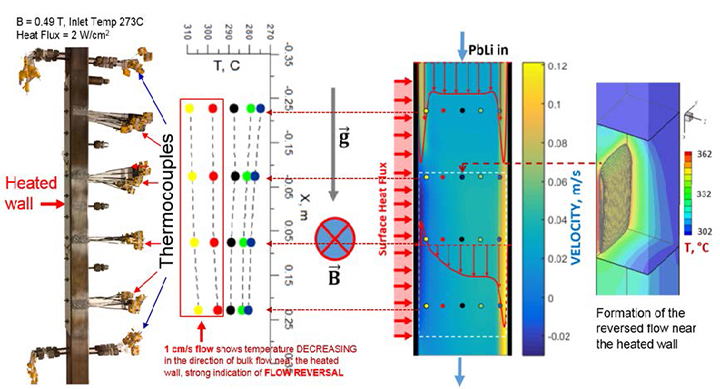

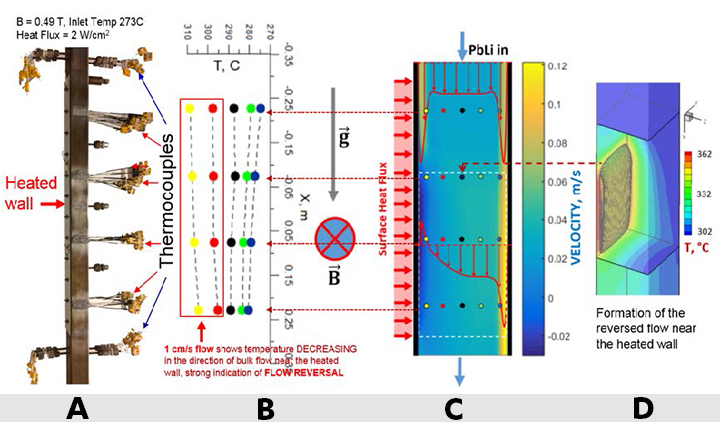

First experiments on a first-of-a-kind multiple-effect facility newly constructed at UCLA in collaboration with EUROfusion confirms recent UCLA scientific discovery A new multiple-effect facility, MaPLE-U, has been constructed at UCLA with funds from the DOE Office of Science/Fusion Energy Sciences and in partnership with EUROfusion and six European Fusion Laboratories. The facility is a first-of-a-kind in the world and has been designed to investigate 3-D MHD thermofluid multiple-effects and material interactions for liquid metal breeder/coolant flow systems for fusion energy. The facility’s construction and commissioning were completed in summer 2018 and the facility started operation in August 2018. The first series of experiments were very successful, and the results provide confirmation of the recent UCLA discovery based on advanced 3-D MHD modeling that multiple-effects such as heating and temperature gradients in addition to gravity and magnetic field result in instabilities and flow reversal in all types of liquid metal blankets. This contrasts with the assumption made by fusion researchers over the past 30 years that the flow is stable and laminar based on separate effect modeling and experiments. The new results on MaPLE-U indicate the need for an intensive program of experiments and modelling to provide an understanding and a new database with which liquid metal blankets can be prudently designed and operated. This research is a key part of the planned US/UCLA-EUROfusion collaboration, and is important for all liquid metal blankets, such as Dual Coolant Lead Lithium (DCLL), Water Cooled Lead Lithium (WCLL) and Helium Cooled Lead Lithium (HCLL), presently selected by world fusion programs for future implementation in ITER, FNSF and DEMO, and eventually for fusion power plants.

MaPLE-U has been designed and constructed with major capabilities to investigate MHD mixed convection flows, material interactions, and effects on tritium transport, corrosion and other phenomena important to understanding and predicting multiple-effects/multiple-interactions in the complex fusion nuclear environment. Unique features of the facility are: prototypical material and operating conditions, lift/tilt system for the 20-ton magnet to provide precise flexible orientation with respect to gravity, high-power heaters with capabilities to provide steep temperature gradients, high-power heat rejection system, high capacity electromagnetic pump, and sophisticated data acquisition and remote control and monitoring system.

During the experiments, heated test blanket submodules are placed into the magnet bore with PbLi flowing through at different orientations with respect to gravity and under different magnetic field, velocity and heat flux conditions to explore and understand their influences on MHD thermofluid multiple-effects/multiple-interactions phenomena. The next generation of test blanket submodules will be equipped with movable probes to allow precise measurements of PbLi in-situ potential, flow velocities and temperatures during the tests. These measurements of the temperature field, flow velocity and induced electric potential are vitally important for: (1) characterization of unstable mixed-convection MHD flows in fusion blanket relevant conditions, (2) validation and verification of the 3-D numerical codes that will eventually be used as blanket design & analysis tools, (3) characterization of heat & mass transfer (corrosion and tritium transport) in the blanket flows, and (4) improvement of existing liquid metal blanket designs and exploring even more attractive blanket concepts.

(A) Experimental stainless steel test-article with surface heaters and temperature diagnostics,

(B) Temperature field measurements showing signature of flow reversal,

(C) Computed velocity profiles within the heated zone,

(D) Computed zero flow “bubble” showing flow reversal near the heated wall.

The research and design team led by Prof. Mohamed Abdou (UCLA) and Dr. Gianfranco Federici (EUROfusion) includes world-class experts in the areas of fusion nuclear science, liquid metal MHD, heat & mass transfer and material science. Among them are senior researchers from UCLA: Dr. Sergey Smolentsev, Dr. Cyril Courtessole, Dr. Neil B. Morley and Dr. Alice Ying; and from the EU: Dr. Marco Utili (ENEA, Italy), Dr. Leo Buehler, Dr. Chiara Mistrangelo (KIT, Germany), Dr. David Rapisarda, Dr. Maria Gonzalez (CIEMAT, Spain) and Dr. Fabio Cismondi (EUROfusion). Significant contributions were also made by Ph.D. students and post-doctoral researchers: Alessandro Venturini, Yi Yan, Gautam Pulugundla, Carlota Soto, Belit Garcinuño, Tyler Rhodes, Fernando Urgorri and Alessandro Tassone; and by engineers and technicians: Tom Sketchley, Massimo Valdiserri and Andrea Malavasi. Several companies from the USA and Europe contributed to the facility design, safety analysis and construction: Shore Western USA (Lift/tilt system for the magnet), SAAS Germany (EM pump), ENGLEKIRK USA (Seismic/safety analysis) and SIMICH USA (Installation of the base platform).